In urban management, choosing the right materials is essential to ensure the durability and safety of public places. While traditional bollards made from concrete, steel, or cast iron are known for their robustness, they have significant limitations, particularly in terms of maintenance and impact resistance. In this article, we present the technical advantages of flexible polyurethane bollards compared to traditional ones, and why their implementation is a better choice.

Limitations of traditional bollards

Traditional bollards have been widely used for their strength. However, they have several key disadvantages:

- Constant maintenance required: Due to impacts,concrete, steel, or cast iron bollards can suffer significant damages. A single collision can render them unusable, forcing them to be replaced.

- Vulnerability to weather: The passage of time, together with environmental factors such as rain, snow, and corrosion, affect their structure, accelerating deterioration and requiring periodic replacements.

The solution: Flexible polyurethane bollards

Superior strength and safety

Our flexible bollards, made from high-quality polyurethane, offer a range of technical benefits that outperform traditional versions.

Impact resistance

Thanks to their flexible material, polyurethane bollards can withstand up to 1,000 impacts without breaking and return to their upright position. This feature ensures a considerably longer lifespan.

Safety for pedestrians and vehicles

Being flexible, these bollards not only reduce the risk of vehicle damage but also minimise potential injuries to pedestrians in case of contact.

Zero maintenance

These bollards require no additional maintenance as polyurethane does not rust or deteriorate due to adverse weather conditions. Their resistance to corrosion and wear makes them a long-term investment.

Models and flexibility grades

To meet different urban needs, we offer several bollard models, and here we highlight two of them.

Both models are identical in shape and size, differing only in their flexibility and recovery capabilities.

Bollard installation methods

Our bollards are designed to suit various installation needs, offering two main methods:

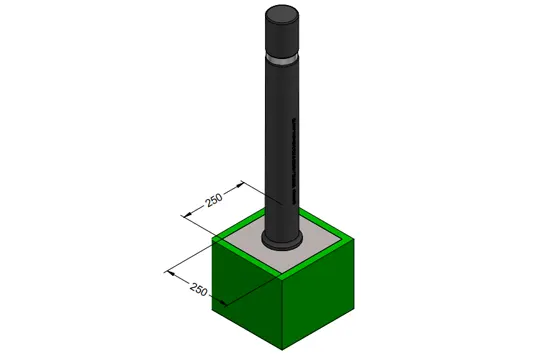

Fixed installation

This method involves creating a 250x250x250 mm hole, which is then filled with concrete. The bollard is inserted into the hole, providing stable and permanent fixation.

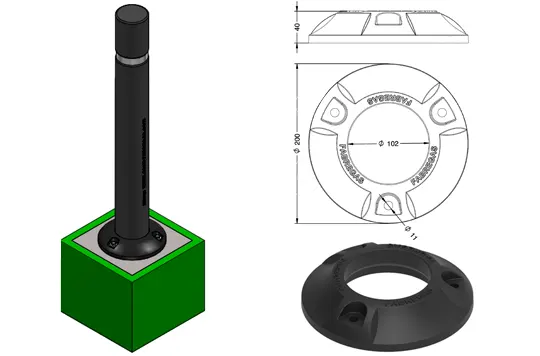

Bolted installation

In this case, a floor bolt fixing system using M8 screws is used. A similar hole is drilled as in the fixed method, but three additional holes are added for the screws, ensuring firm attachment. To simplify this installation, we offer the C-430-TPU-ARO-AT ring in our catalogue, an optimised solution for secure and quick installation.

Removable bases options

For situations where the bollard needs to be regularly removed to allow vehicle access, we provide two systems of removable bases:

Steel base

Embedded in the ground, this base allows the bollard to be secured and removed as needed using a square socket key.

Polyethylene base

Similar in function, this base includes a cover that conceals the hole when the bollard is not installed. Additionally, it is secure with a screw to the cover, keeping the area free of obstacles when not in use.

Flexible polyurethane bollards represent a clear advancement over traditional concrete or steel versions. With their impact resistance, durability to different weather conditions, and low maintenance, our bollards offer a technical, safe, and cost-effective solution for managing urban spaces. Furthermore, with various models and installation methods, we meet all our clients’ needs, providing flexible and adaptable solutions.

If you require any further specifications or want to place an order, please do not hesitate to contact us.